Overview of the Partnership

On September 22, 2025, Xinhua reported on a deepening robotics partnership between China and Italy, especially around the company EFORT Intelligent Robot Co. in Wuhu, Anhui Province. The collaboration involves Italian-engineered technologies being integrated into Chinese manufacturing, especially in painting robotics, motion control, and integration systems. An example: Luca Samar, an Italian software engineer, regularly travels to Wuhu to work with EFORT’s team to optimize simulation systems for painting robots.

EFORT has acquired several Italian robotics firms since 2015 to build up its R&D in robotics, particularly to leverage Italy’s creative and technical strengths in robotics innovation.

What’s Actually Happening & Why It Matters

- Production & Export Growth: In 2024, EFORT sold over 16,000 industrial robots, serving sectors like electronics, photovoltaics, auto parts, shipbuilding. It also began exporting its robots to Europe from 2019.

- Technological Innovation: The robotics now increasingly use AI, machine vision, and large-scenario data to automate tasks once requiring manual programming—such as welding. This lowers the entry barrier for small and medium-sized enterprises.

- Joint R&D and Market Access: EFORT leverages Italian know-how to enhance its robotics capabilities, while Italian firms gain better access to the vast Chinese market. Cooperation also includes setting up joint research centers (for example, a new robotics research center tied to Italy’s Advanced Robotics & Enabling Digital Technologies & Systems 4.0, and innovation centers in China).

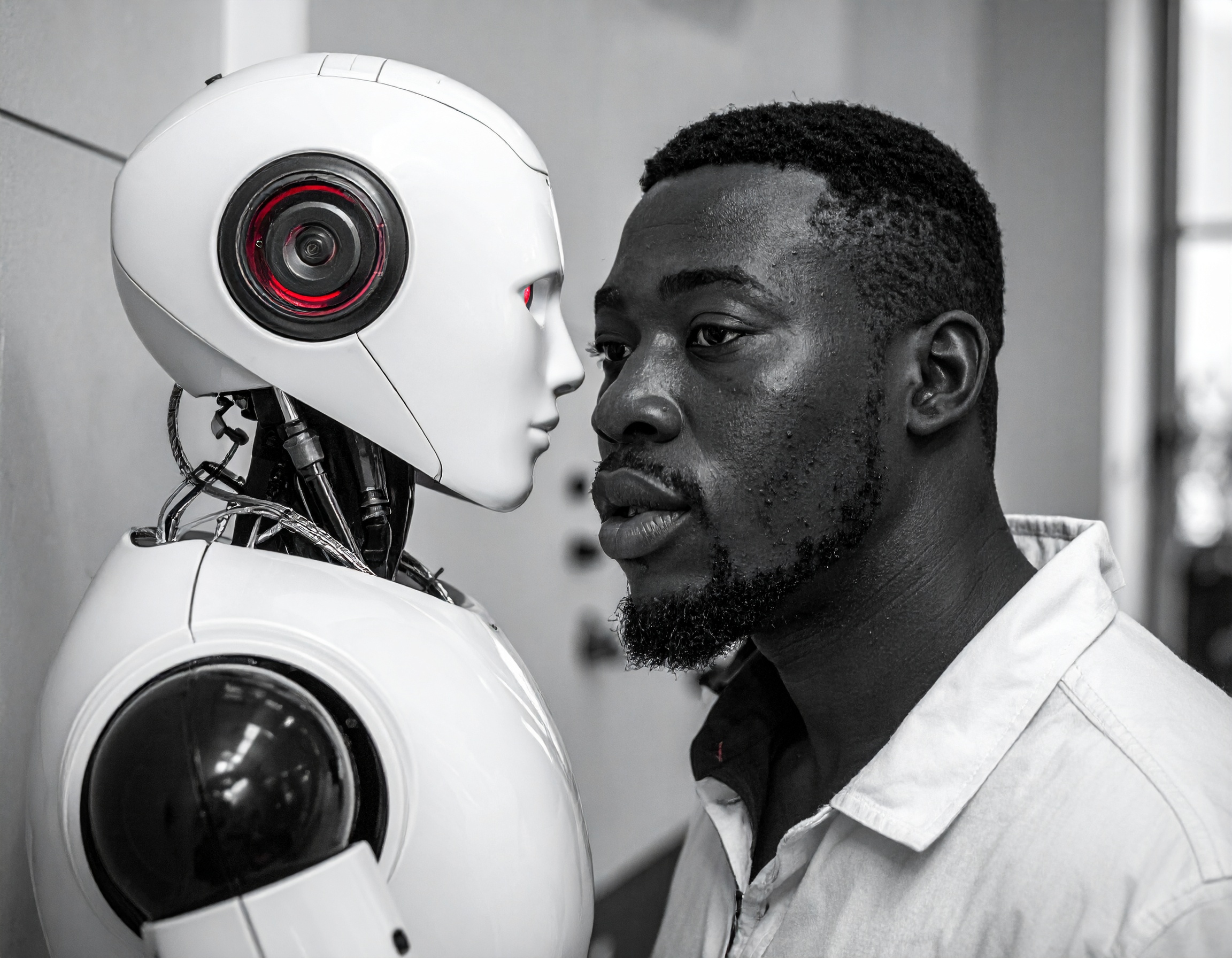

Implications: The Rise of AI Employees, Non-Human Workers, and Voice AI Agents

While the report doesn’t specifically mention “Voice AI Agents,” the trend toward AI-powered non-human workers (robots guided by machine vision, AI, and automated programming) is strongly evident. These “AI Employees” are transforming manufacturing in several ways:

- They can perform tasks autonomously (e.g. welding, assembly, painting) without needing continuous human supervision or programming.

- They lower barriers for SMEs to adopt robotics, due to lower technical demands and more accessible automation.

- They are driven by the global demand for efficiency, precision, and scalablity in production.

Why It’s Important

This partnership is significant because:

- It demonstrates how international collaboration (between nations with complementary strengths: Italian robotics innovation and China’s scale, market, and manufacturing base) can accelerate the development and adoption of advanced robotics.

- The shift makes non-human workers more intelligent and capable, which could reshape the workforce – especially in manufacturing, where human roles may shift toward oversight, design, maintenance, and creative tasks.

- For countries and companies, it provides a roadmap for how to integrate AI employees into production in cost-effective ways.

Key Highlights:

- EFORT and Italian partners jointly develop painting robots and simulation systems; regular technical exchanges (e.g., with software engineer Luca Samar) to iterate the systems.

- EFORT sold over 16,000 industrial robots in 2024; since 2019 it has been exporting robots to Europe.

- Use of AI, machine vision, and mass scenario data allow tasks like welding to be done without manual programming, reducing barrier for SMEs.

- Joint research agreements are being forged to further innovation and leverage both Chinese manufacturing scale and Italian technical expertise.

Reference:

https://english.news.cn/20250922/0857864301d74112907d00e2178d3475/c.html