Revolutionizing Factories: Toyota Unleashes Digital Employees for Enhanced Industrial Productivity!

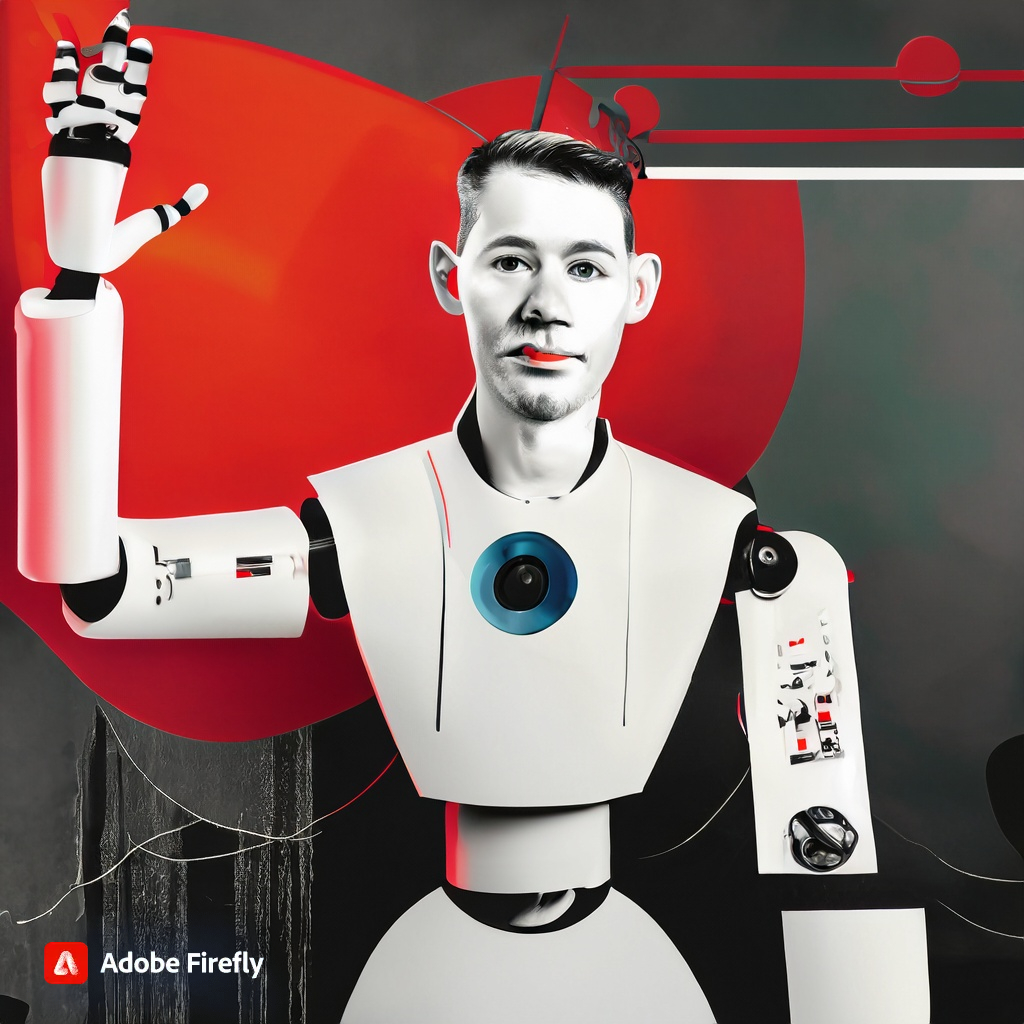

Toyota has embarked on a transformative journey in the manufacturing sector, introducing Intelligent Agents as the newest addition to factory floors. These Digital Employees signify a monumental shift in industrial automation, promising heightened efficiency and precision in manufacturing processes.

Toyota's Intelligent Agents, equipped with state-of-the-art sensors and machine learning capabilities, are designed to seamlessly integrate into factory workflows. These non-human workers are not mere machines; they are adaptable entities that learn from their surroundings and optimize production lines with minimal human intervention. The implications for increased productivity and reduced operational costs are staggering.

The Wired article details specific instances where Toyota's Digital Employees have revolutionized production lines, showcasing their ability to perform complex tasks with unparalleled accuracy. From assembly line operations to quality control, these Intelligent Agents demonstrate a level of sophistication that heralds a new era in manufacturing. Toyota's strategic move in this direction not only cements its position as an industry pioneer but also sets a precedent for the integration of artificial intelligence in large-scale industrial settings.

The significance of this development extends beyond Toyota's factories. The adoption of Digital Employees in manufacturing processes could potentially redefine the global industrial landscape. As more companies follow suit, we may witness a paradigm shift in how goods are produced, with Intelligent Agents becoming indispensable assets in enhancing both speed and precision. Toyota's venture into this realm is not merely an upgrade in technology; it is a bold step towards reshaping the future of industrial work.

In conclusion, Toyota's introduction of Intelligent Agents into factory environments marks a watershed moment in the evolution of industrial automation. As Digital Employees become an integral part of production processes, the repercussions for efficiency, cost-effectiveness, and overall manufacturing capabilities are profound. This leap into a new era of automation prompts us to ponder the transformative impact these technologies will have on the global manufacturing landscape.

Key Highlights:

- Toyota's Technological Leap: Toyota has recently unveiled Intelligent Agents, sophisticated robots equipped with advanced machine learning algorithms. This move signals a significant advancement in automation, with potential applications ranging from household chores to industrial manufacturing.

- Adaptive Learning Capabilities: These Intelligent Agents are not static machines but dynamic Digital Employees capable of learning and adapting to their environment over time. The technology allows them to optimize tasks such as housework or factory operations with minimal human intervention.

- Household Revolution: In domestic settings, Toyota's Digital Employees showcase their prowess by learning to navigate homes, distinguish between various objects, and enhance their efficiency with each chore. Families could soon have reliable and intelligent assistants that significantly reduce the time spent on routine tasks.

- Industrial Transformation: Toyota's foray into Intelligent Agents extends to the manufacturing sector. The robots are introduced to factory floors, demonstrating their ability to revolutionize production lines by performing complex tasks with unparalleled accuracy. This move has far-reaching implications for industrial productivity and cost-effectiveness.

- Paradigm Shift in Work Dynamics: The integration of Intelligent Agents into various settings prompts a broader discussion on the future of work. As non-human workers become integral to daily life and production processes, the landscape of work and technology integration is poised for a significant transformation.

- Global Implications: Toyota's strategic move in adopting Intelligent Agents sets a precedent for industries worldwide. The ripple effect could redefine how goods are produced globally, with other companies likely to follow suit, leading to a fundamental shift in the industrial landscape.

- Pioneer in Automation: Toyota's venture into this cutting-edge technology positions the company as a pioneer in automation, showcasing its commitment to pushing the boundaries of what's possible in integrating artificial intelligence into various aspects of life and work.

Reference:

https://www.wired.com/story/fast-forward-toyota-robots-learning-housework/