Artificial Intelligence in Manufacturing: From Factory Automation to ROI

Artificial intelligence is revolutionizing manufacturing by enabling autonomous operations, optimizing workflows, and minimizing errors. In production environments, AI-powered tools in manufacturing ensure quality control, safety monitoring, and predictive maintenance. The technology delivers key advantages, including accurate demand forecasting, reduced downtime, and faster quality improvements. Through predictive models, manufacturers achieve measurable results that directly impact profitability.

AI's most valuable capability is identifying potential equipment failures before they occur. This proactive approach enables maintenance teams to respond promptly and resolve issues effectively. Work teams can optimize processes, balance resource allocation, and manage inventory effectively. Artificial intelligence in manufacturing enables continuous quality control by detecting defects invisible to human inspectors. This technology enables businesses to stay competitive through intelligent and adaptive manufacturing practices.

Understanding AI in the Manufacturing Industry

Artificial intelligence extends far beyond routine automation. To fully leverage its potential, manufacturers must understand the difference between basic automation and intelligent systems. Basic automation performs repetitive tasks according to fixed programming. Intelligent systems employ a comprehensive approach, learning from data and continuously adapting to changing conditions. Modern AI systems in manufacturing integrate multiple technologies to achieve cost-effective investment and maximum productivity. Here are the key applications of manufacturing AI:

- Machine Learning for Predictive Maintenance. Machine learning algorithms analyze sensor data to predict equipment failures before they happen. This reduces unplanned downtime, lowers maintenance costs, and ensures continuous operation across production lines.

- Computer Vision for Quality Control. AI-powered camera systems equipped with advanced sensors detect defects and inconsistencies throughout the production process. This ensures strict quality standards, reduces human error, minimizes recall risks, and cuts material waste.

- Natural Language Processing for Supply Chain Optimization. NLP systems process supplier data, interpret reports, and streamline communication. This improves coordination, identifies supply chain bottlenecks, and increases transparency throughout operations.

Benefits of AI in Manufacturing: Why It Matters

AI implementation enhances manufacturing operations, making them safer and more profitable. AI systems learn from data and adapt to changing conditions in real time. Integrating AI throughout supply chains can significantly reduce costs and improve product quality. Here are the key benefits of AI in the manufacturing industry:

- Reduced Downtime. AI systems predict equipment failures across entire production lines, minimizing unplanned downtime and maximizing operational continuity.

- Lower Production Costs. AI optimizes resource allocation, reduces waste, and eliminates inefficiencies throughout manufacturing operations.

- Predictive Demand Planning. Machine learning algorithms analyze historical data and current market trends to accurately forecast demand. Companies maintain optimal inventory levels, preventing both shortages and excess stock.

- Real-Time Defect Detection. Computer vision systems identify defects and quality issues the moment they occur, enabling immediate corrective action.

- Enhanced Worker Safety. AI-powered robotics and monitoring systems reduce workplace injuries by warning personnel about potential hazards before incidents occur.

- Improved Decision-Making. AI analyzes vast amounts of data to extract actionable insights, enabling faster and more accurate business decisions.

Cost Reduction and Efficiency Gains

AI drives significant cost reductions and efficiency improvements across manufacturing operations. The primary advantage is waste minimization through real-time analysis of production data. AI algorithms identify waste sources and detect defects as they occur. Real-time process control allows companies to reduce material costs while boosting productivity. Artificial intelligence in manufacturing directly supports sustainable development goals.

Machine learning models also control and optimize energy consumption. By predicting peak usage periods, production facilities can minimize energy consumption and manage their usage more effectively. This reduces utility expenses, particularly during continuous operations, while lessening environmental impact.

AI identifies bottlenecks and problem areas before they disrupt production. Predictive planning and proactive maintenance ensure continuous operation. By reducing waste and optimizing processes, AI manufacturing solutions directly increase profitability. Manufacturing enterprises can maintain strong competitive positions through improved efficiency.

Quality Control and Defect Detection

AI delivers exceptional productivity improvements in quality control. AI systems detect various defects with remarkable precision. Modern factories deploy AI-powered camera systems throughout their production lines. These cameras have high-resolution sensors that capture detailed images at every stage. AI models analyze images to identify cracks, surface irregularities, and other defects with greater accuracy than human inspection. AI for manufacturing excels because, unlike human workers, AI systems maintain consistent performance without fatigue. Machine learning continuously improves through exposure to larger datasets.

Continuous data processing enhances system accuracy over time. AI responds instantly to quality issues and sends immediate notifications. Manufacturers can take corrective action quickly to minimize errors. Preventing defective products from reaching customers is crucial for business competitiveness. The main advantages include reduced product returns through defect elimination. Customers remain satisfied through rigorous quality control. AI in the manufacturing industry improves operational efficiency substantially. Automated inspection reduces manual workload and transforms traditional quality assurance approaches.

AI Applications in Factory Automation

AI is taking manufacturing to new levels of capability. Factory equipment is becoming increasingly flexible and intelligent through the integration of AI. AI helps robots and CNC machines adapt dynamically through continuous data analysis.

- AI-Powered Robotics. AI-based robots handle complex tasks using computer vision and machine learning. These systems detect errors and recognize objects continuously during operation.

- Intelligent CNC Machines. AI in factory automation enables more sophisticated CNC operations. AI-based systems optimize entire workflows, minimizing downtime and improving overall equipment effectiveness.

- Adaptive Automation. Adaptive automation represents a significant advance over traditional systems. AI-powered adaptive automation reconfigures workflows dynamically based on real-time production needs.

- Predictive Scheduling. Predictive scheduling analyzes production data to anticipate delays and maintenance requirements. Assembly lines in smart factories using this technology ensure on-time delivery while reducing downtime.

- Autonomous Optimization. Manufacturing with AI includes autonomous optimization of entire production networks. Systems integrate logistics and production from raw material delivery through finished product creation. AI-controlled logistics autonomously coordinate material movements to eliminate bottlenecks.

Predictive Maintenance with AI

Companies increasingly use AI-powered predictive maintenance to address operational challenges. This approach predicts and prevents equipment failures by analyzing sensor data and machine logs. Here's how the process works:

- Data Collection. Sensors continuously record temperature, pressure, vibration, and other operational parameters. Data collection helps identify warning signals from equipment before failures occur.

- Machine Learning Analysis. Manufacturing AI employs machine learning to process sensor data and detect failure patterns. Systems can predict when specific components are likely to fail.

- Automated Alerts. After data collection and analysis, the system generates automatic notifications. Maintenance teams receive alerts about required interventions and can schedule repairs proactively.

The main advantages of this approach include dramatically reduced downtime. Production can operate continuously with minimal interruptions. Timely maintenance reduces equipment wear and prevents catastrophic failures. Companies reduce overall maintenance expenses through targeted interventions. Increased safety and reliability prevent equipment failures that could endanger workers. By understanding how AI is used in manufacturing, companies can achieve substantial operational improvements.

AI for Supply Chain and Inventory Optimization

AI provides reliable solutions for supply chain and inventory optimization. Through the implementation of AI, operations become more predictable, adaptive, and sustainable. Companies move beyond conventional forecasting methods through advanced automation. This enables superior demand forecasting accuracy. Machine learning models analyze historical sales data, seasonal patterns, and current market trends to inform predictions. This analysis enables the prediction of future demand with remarkable precision.

AI adjusts purchase orders dynamically based on real-time conditions. AI detects potential delays and assesses various risk-related factors. Artificial intelligence in industry evaluates all relevant variables and recommends optimal supplier alternatives. Companies maintain continuous material flow and receive necessary components on schedule. Deliveries arrive faster, on time, and without disruption. This minimizes supply chain interruptions and drives operational success.

AI optimizes inventory while accounting for demand variability. This reduces storage costs for products and materials. AI-based platforms track external events and potential supply disruptions. Predictive alerts help companies act quickly and respond to changing conditions. This capability is essential for maintaining resilient supply chains.

AI Manufacturing Solutions: Tools and Platforms

AI in manufacturing delivers numerous benefits that drive business growth. Manufacturing solutions focus on automation and leveraging the right tools. These tools enable data-driven decisions and improve productivity. Here are the key categories of AI-based tools that enhance manufacturing operations:

- MES (Manufacturing Execution Systems). Software platforms that manage manufacturing processes in real time. AI integration with machine learning enables anomaly detection and operational optimization across production lines.

- Digital Twins. Digital twins create virtual replicas of physical assets that simulate real-world conditions, allowing for an accurate representation of these assets. Combined with AI, these systems continually learn from operational data, thereby improving prediction accuracy. This supports predictive maintenance and process innovation.

- IoT Sensors. Smart sensors embedded in equipment continuously monitor operational parameters. AI systems analyze transmitted data to detect potential malfunctions, enabling proactive maintenance.

- AI-Based Robotics. Artificial intelligence in industry is exemplified by advanced robotics. These robots incorporate computer vision systems to enable flexible and precise automation across various manufacturing tasks.

- Analytical Dashboards. Platforms that visualize production data clearly and comprehensively. AI-powered data analytics identify trends, inefficiencies, and opportunities for improvement to support informed decision-making.

The primary integration challenges include compatibility with legacy systems, substantial initial investment requirements, and concerns about data quality. Many manufacturers operate equipment that was installed decades ago, creating significant compatibility issues when integrating modern AI systems. These legacy machines often lack the sensors and connectivity required for AI-driven monitoring and optimization. Retrofitting older equipment with IoT sensors and communication capabilities can be a significant expense that requires careful planning and budgeting.

Data quality presents another critical challenge that can significantly undermine the effectiveness of AI. AI systems require clean, consistent, and comprehensive data to function properly. Many manufacturers discover that their existing data collection practices are inadequate or inconsistent across different production lines. Missing data, measurement errors, and incompatible data formats can severely limit AI performance. Establishing robust data governance policies and investing in data cleaning processes are essential prerequisites for the successful deployment of AI.

The substantial upfront investment required for AI implementation often creates hesitation among decision-makers. Beyond software and hardware costs, companies must also account for system integration expenses, employee training programs, and potential production disruptions that may occur during deployment. However, manufacturers who view AI as a long-term strategic investment rather than a short-term expense typically achieve better outcomes.

Best practices for AI implementation in manufacturing include starting with targeted pilot projects that demonstrate clear value. These pilots should focus on specific, measurable problems where AI can deliver quick wins. Success in initial projects builds organizational confidence and secures funding for broader deployment. Investing in robust data management infrastructure from the beginning prevents costly rework later. Training staff on AI capabilities ensures that employees can effectively utilize new systems and contribute to continuous improvement. Selecting open, modular systems that integrate with existing equipment provides flexibility as technology evolves and business needs change.

Computer Vision in Smart Factories

Computer vision in smart factories is essential for comprehensive quality control. Smart factories can monitor every stage of production in real-time. The primary function is continuous production monitoring. Cameras are positioned at all critical stages to capture operational data. AI algorithms monitor production flow and detect issues as they emerge.

Computer vision detects defects and irregularities that require correction. Systems continuously improve accuracy and reliability. Modern systems exceed human inspection capabilities and eliminate common errors. The main benefits include dramatically reduced inspection time and minimized defect rates.

AI in the manufacturing industry is crucial for ensuring safety and compliance. Cameras monitor worker movements and verify adherence to safety protocols. Systems detect unsafe actions and conditions that could endanger workers. The primary benefits include reduced workplace accidents and adherence to strict regulatory compliance.

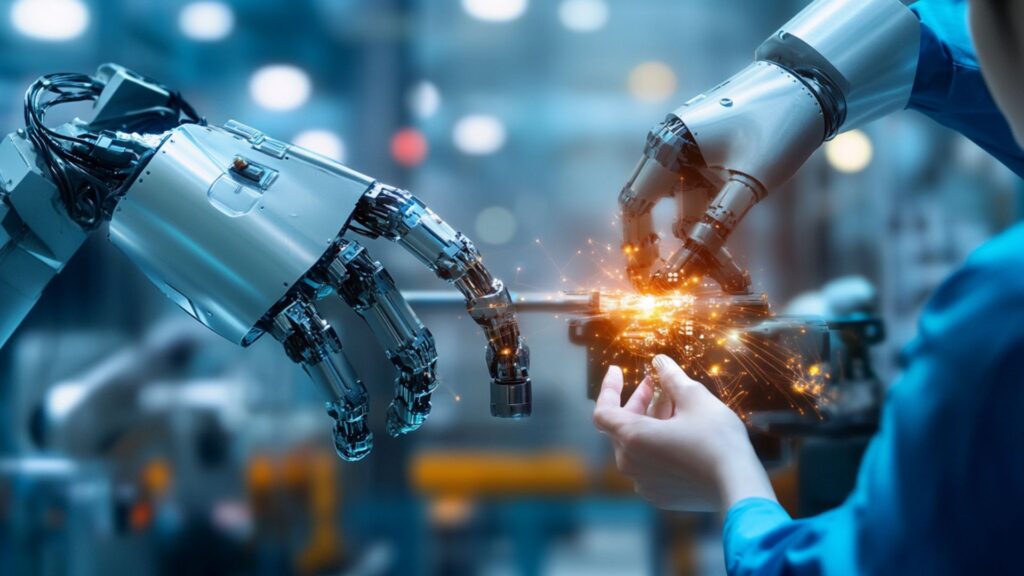

AI-Driven Workforce Augmentation

Workforce augmentation represents an essential evolution in manufacturing. This transformation is driven by automation and AI technologies. AI serves as a powerful tool that augments rather than replaces human workers. AI provides valuable support for process optimization. AI delivers real-time analytics that help workers perform more effectively. This enables error correction and operational excellence. Guidance using augmented reality for assembly is becoming increasingly common. Artificial intelligence in manufacturing enhances safety by identifying and preventing dangerous situations. This accelerates workflows and reduces defect rates. Workers receive automated reporting that streamlines administrative tasks. With AI support, production maintains consistent performance, achieves operational goals, and remains highly competitive.

Future of AI in Manufacturing: From Smart Factories to ROI Maximization

AI in factory automation is reaching new levels of sophistication. Implementing reliable systems helps automate complex tasks and coordinate operations effectively. The future of manufacturing extends from fully autonomous smart factories to maximize return on investment. Here are the emerging technological developments and their characteristics:

- Hyperautomation. AI combines machine learning, computer vision, and other advanced systems for comprehensive automation. This accelerates cycle times and delivers measurable results. Companies can significantly reduce per-unit labor costs.

- Self-Optimizing Factories. AI manufacturing solutions will increasingly include self-optimizing capabilities. Advanced digital twins and machine learning models will simulate operational changes in real time. Companies will test and optimize their processes virtually, managing production speed, quality, and energy consumption dynamically. Rapid adaptation to changing conditions will become standard practice.

- Integration with 5G. AI-powered systems deployed on high-speed 5G networks will enable unprecedented coordination and synchronization. Manufacturing operations will achieve seamless collaboration while reducing dependence on traditional infrastructure.

- Edge Computing. Edge computing will enhance AI capabilities by processing data locally. AI will continue to augment the workforce in essential areas rather than replacing human expertise.

The benefits of AI in manufacturing are transforming the industry and delivering substantial advantages. Manufacturers should consider the ethical and social implications, including the retraining needs of workers. Investing in comprehensive training programs will help workers master valuable AI tools. Transparency and responsible data management are essential for maintaining stakeholder trust. Cybersecurity plays an increasingly critical role as factories become more connected and digitized. AI implementation can be viewed in both short-term (up to two years) and long-term (five years or more) timeframes. Over time, factories will develop new business models, reduce operational costs, and achieve unprecedented levels of efficiency.

Conclusion: Key Takeaways for Manufacturers

AI for manufacturing is a transformative force and a powerful tool for improvement. Artificial intelligence represents far more than a passing trend. AI is fundamentally transforming workflows and revolutionizing operations. The technology impacts everything from factory floors to executive boardrooms. ROI depends on implementing a balanced, strategic approach. Manufacturers must develop clear strategies for AI adoption. Selecting appropriate tools directly affects operational results and overall efficiency. AI delivers high-quality data insights and requires a skilled workforce for optimal implementation. AI in manufacturing is becoming the primary path to achieving competitive excellence. Manufacturers should initiate pilot projects to demonstrate value and establish organizational confidence. Measuring ROI carefully helps allocate budgets appropriately. Scaling should proceed gradually and strategically to ensure safety and operational stability. Strategic implementation will enable manufacturers to achieve new performance levels and maintain consistent productivity.