Non-Human Workers Gear Up: How Automakers Are Turning to AI and Robots for a Manufacturing Reboot

Shifting Gears in the Auto Industry

On 3 November 2025, the industry newsletter DIGITIMES Asia published a report revealing that as the electric-vehicle (EV) market approaches maturity and the growth momentum begins to slow, automakers are starting a strategic pivot: instead of relying solely on traditional vehicle production, they are accelerating investments in artificial intelligence (AI), robotics and automation.

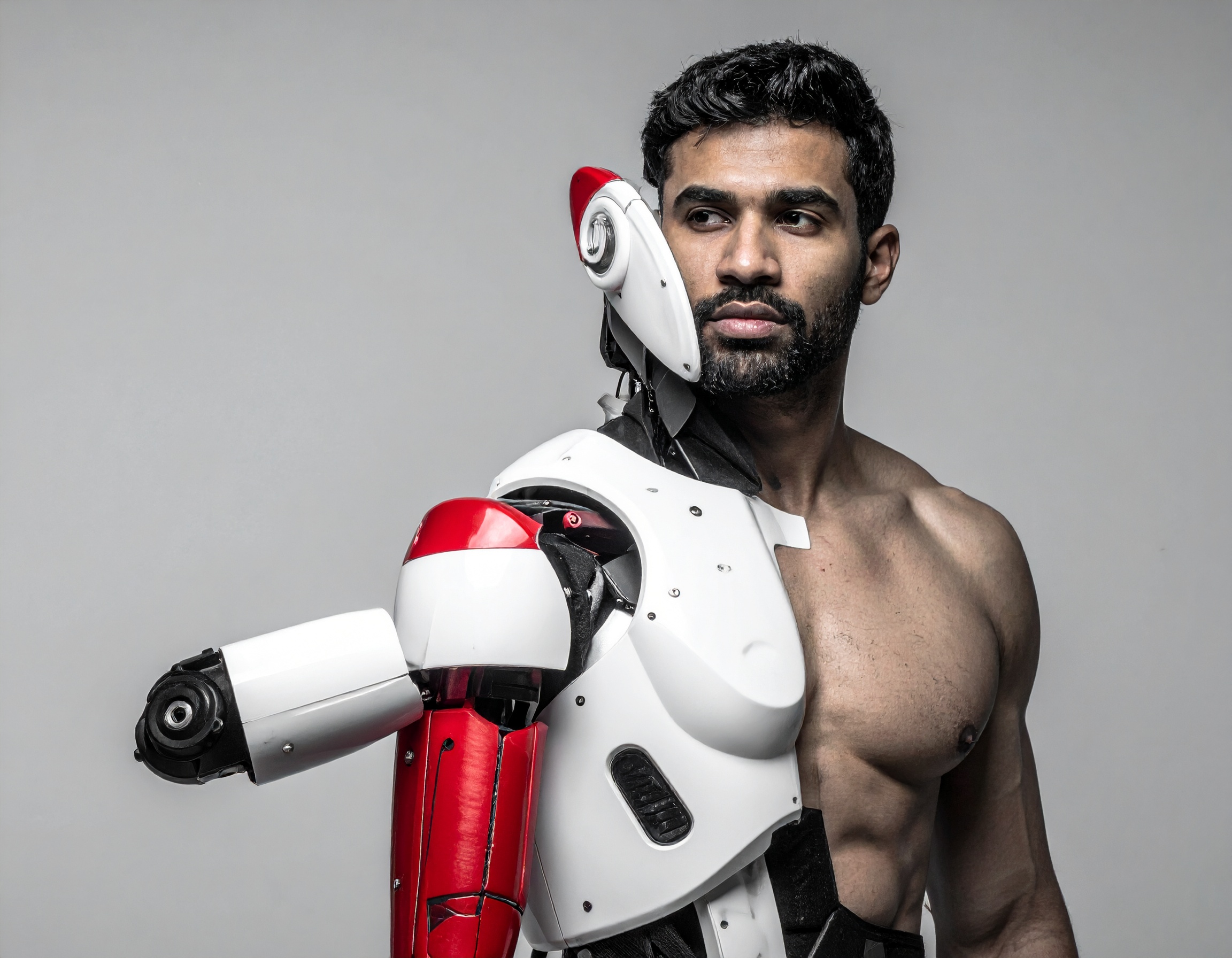

In essence, manufacturers are preparing their “second curve” of growth — the transformation of factories into smart, automated hubs, populated by “AI Employees”, “Voice AI Agents”, and other Non-Human Workers.

What’s Happening — and Why It Matters

Here are the key facts and examples:

- The EV market’s rapid rise is losing steam, especially in major markets, prompting car-makers to rethink their production paradigms.

- Automakers are now deploying humanoid robots and other AI-driven systems in their plants to improve manufacturing efficiency and flexibility.

- This shift is important because moving into robotics and “smart factories” helps mitigate fluctuating demand for vehicles, reduce labour-cost pressures, and build resiliency into global supply chains.

- The article identifies automation and robotics as the new frontier for competitiveness in the automotive sector, rather than pure volume growth of vehicles.

Thus the significance: the industry is signalling that pure production growth may no longer be sufficient — creating a new kind of workforce made up of Non-Human Workers could be the next big competitive differentiator.

The Implications for Manufacturers and Workers

The move toward AI, robotics and smart manufacturing has broad implications. For manufacturers, it opens up new opportunities for cost savings, higher precision, and rapid adaptation as product-cycles and consumer demands shift. For workers, it suggests a transformation of roles: rather than manual assembly lines, humans may increasingly work alongside “AI Employees” and robotics systems, with different skill-sets needed (programming, oversight, optimization).

Furthermore, this transformation may reshape global supply chains: factories with advanced automation can localize production more easily, respond to leaner volumes and tailor output faster. And for the EV market itself, it means that even if sales growth slows, there is still a path forward to profitability and innovation through smarter factories rather than simply more vehicles.

Key Highlights:

- Automakers are accelerating implementation of robotics and AI due to slowing growth in the EV market.

- “Non-Human Workers” such as humanoid robots and AI-driven systems are becoming integral to smart factory strategies.

- The transition to smart manufacturing offers a new growth axis for the auto industry, beyond vehicle sales.

- Human workers will need to adapt, shifting toward roles that interface with or manage the new automated workforce.

- Global supply-chain resilience and manufacturing flexibility are enhanced by this automation push.

Reference:

https://www.digitimes.com/news/a20251103PD224/market-vehicle-growth-auto-industry-automakers.html